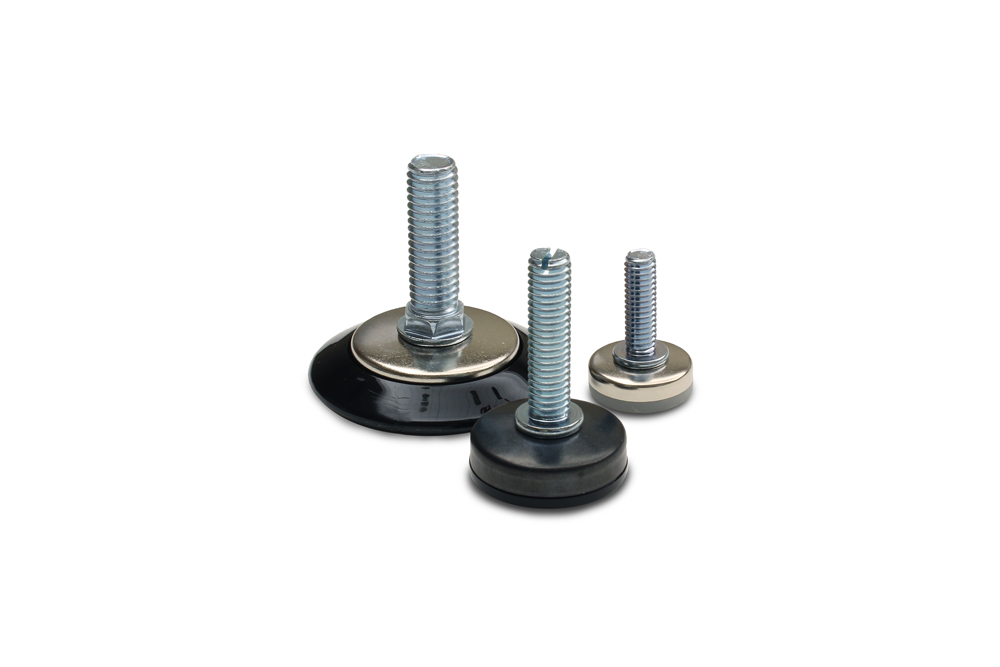

Adjustable Glide Selections Guide

Guide for Office Furniture Glides and Levelers for Desks, Tables and

Point-of-Purchase (POP) Display Racks

There are many styles, sizes and types of adjustable glides and levelers suitable for office furniture, point-of- purchase (POP) display racks or other similar applications. There are also several considerations when choosing the right glide or leveler for the furniture application. These include aesthetics, or the desired appearance of the adjustable glide; static strength, which is how much load the glide can hold before deformation and/or failure; lateral strength which is how much side to side stability the glide offers; impact strength, which is how much of a blow or drop can the glide survive; and lastly, economics or price. Typically adjustable furniture glides that have great strength and good aesthetics are more expensive than weaker, less attractive furniture glides, but of course there are exceptions, and sometimes some of the simplest, smallest and most economical glides can be the strongest. Below are several considerations when choosing adjustable glides:

Click on a heading to advance to the appropriate section:

Light Duty Adjustable Glides

Light Duty Adjustable Glides

Furniture glides in this category typically are made of lower cost and lower strength materials such as polyethylene. These glides are usually sufficient for light duty applications such as lighter tables, desks, pedestals or cabinets that do not bear much weight and are a good option where cost is a primary concern. These adjustable glides not only use lower cost materials but also are of a lighter construction. They are available with light gage decorative metal shells which offer some aesthetic value but not much additional strength. Examples of these are Carpin’s Emperor/Empress adjustable glides.

Heavy Duty Adjustable Glides

Heavy Duty Adjustable Glides

Furniture levelers on this category are much more durable than the light duty adjustable glides for several reasons. In most cases these glides feature a decorative shell, but unlike the shells offered on the light duty glides, the shell on the heavy duty adjustable glides is made from a thicker gage steel, thick enough to provide strength to the glide. Furthermore the general construction of the glide is thicker and beefier and therefore can handle much more load and abuse than the light duty varieties. These heavy duty levelers are typically used on conference room tables, heavier desks, restaurant furniture and point of purchase (POP) display racks. Examples of these adjustable glides are Carpin’s Hank heavy duty adjustable glides.

Materials

All else being equal, the choice of materials used on adjustable glides has everything to do with glide performance and economics. Lower cost and lower strength materials such as polyethylene perform much differently than nylon, a material which is commonly used for more rugged and more demanding applications. Nylon, being a much stiffer material than polyethylene, can hold much more weight before deformation and therefore a table with nylon glides can hold much more weight, without deformation or failure, than can the same glides made of polyethylene. Drawbacks of nylon are, of course, economics since a nylon component may cost twice as much as a polyethylene one. Also, because nylon is stiffer, severe impacts on the glides such as raising and dropping a desk or the glide colliding with an impediment, can cause cracking and subsequent failure. If these are legitimate concerns special versions of nylon can be used that offer improved impact resistance over standard nylons.

back to top

Threaded Stem Options

The threaded stem, sometimes referred to as the stud or screw, on the glide or leveler is the means by which the glide is adjusted and the furniture or display is leveled. Various features and styles of stems can be attached to almost any glide.

Stem thread size: the most common threaded stem sizes used on furniture glides are 1/4-20, 5/16-18, 3/18-16, M10, M14 and M18. Load and adjustability should be considered when choosing the proper stem for the glide application. Typically 1/4-20 and M10 stems, being the smallest in diameter and therefore the weakest of the common options, are not usually used in lengths greater than 3” since any unsupported length greater than 3” is highly susceptible to bending of the stem which will result in failure. For larger diameter stems this is usually not a concern.

Adjustment hex: a very common feature for adjustable glides is for the stem to have an adjustment hex at the bottom of the stem by which end users can use a wrench to adjust the furniture glide in or out and raise or lower, or level, the piece of furniture. This feature is standard on most heavy duty glides since the furniture they support is heavier and more difficult to level without an adjustment hex.

Adjustment hex: a very common feature for adjustable glides is for the stem to have an adjustment hex at the bottom of the stem by which end users can use a wrench to adjust the furniture glide in or out and raise or lower, or level, the piece of furniture. This feature is standard on most heavy duty glides since the furniture they support is heavier and more difficult to level without an adjustment hex.

Adjustment slot: a less common feature for levelers, is a slot on the end of the stem. This allows the user to adjust the height of the glide and level the furniture from above. This is a common feature for glides used on office panel systems, point-of-purchase (POP) display racks where there is easy access to the top of the stem.

Adjustment slot: a less common feature for levelers, is a slot on the end of the stem. This allows the user to adjust the height of the glide and level the furniture from above. This is a common feature for glides used on office panel systems, point-of-purchase (POP) display racks where there is easy access to the top of the stem.